Basic Data

Basic Type:

1.Insulated una style conductor

2.Twin style conductor

3.Un insulatas funis finem manicas

Characteres

Totalis sectionis crucis: 0.25~ 150mm²

Color-coding et tubi dimensionum ad DIN 46228, pars 4(0.5~50mm)

Halide liberum, flamma retardare potest accipere

Calor resistens 105℃(PP) 120℃ (PA)

Materia:

XCIX% pura aeris

Synthetica: Polypropylene (PP), Polyamide (PA)

Superficies

Tin-patella praesidio in corrosione

Ordo info

Nunc etiam in promptu sunt pixides plasticae manus pro minoribus requisitis.In communibus adiunctis non habemus MOQ postulationem pro sacculo packaging.

Technical data

Materiam conductivam (praeter Velox Iungo dolor)

| Copper | 99.9% pure |

| Distrahentes fortitudo | 200MPa |

| Ductile Rating | 35% |

| Final Metal State | Pars producti annealed |

| Oxygen Content | 50ppm max |

|

|

|

| Brass | 30% Zinc 70% Copper |

| Distrahentes fortitudo | 580 Mpa |

| Ductile Rating | 6% min |

| Final Metal State | Pars producti annealed |

|

|

|

| Materia | Tin |

| Tin Content | 99.90% |

| Alia Metalla | Duc + Antimonium |

| Plating Crassitudo | 1.5 microns |

|

|

|

| General Conductivity | 98.5% IACS |

| Totalis Resistivity | 1.738 micro-olim cm |

|

|

|

| Materia | PVC omnibus exceptis nylon 6 vel nylon 66 - pro IQC . |

| Naufragii voltage | 1.5 k V(min) |

| Nulla resistentia | Super C ohms meg |

| voltage opus | Usque ad 300V AC / DC * |

|

|

|

| Pre-Insulate | -40℃ ad +150℃ |

| Brass | 145 |

| plumbum inauratum | 160℃ |

SPECIFICATION

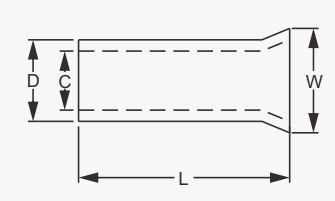

| Crucis sectionem (mm²) | Item No. | Dimensiones (mm) | AWG |

| Crucis sectionem (mm²) | Item No. | Dimensiones (mm) | AWG | ||||||

| L | W | D | C |

| L | W | D | C | ||||||

| 0.25 | EN0206 | 6 | 1.5 | 1.1 | 0.8 | #26 |

| 10 | EN10-18 | 18 | 5.8 | 4.9 | 4.5 | #8 |

| EN0208 | 8 |

| EN10-20 | 20 | ||||||||||

| 0.34 | EN0306 | 6 | #24 |

| EN10-25 | 25 | ||||||||

| EN0308 | 8 |

| 16 | EN16-12 | 12 | 7.2 | 6.2 | 5.8 | #6 | |||||

| 0.5 | EN0506 | 6 | 1.7 | 1.3 | `1.0 | #22 |

| EN16-16 | 16 | |||||

| EN0508 | 8 |

| EN16-18 | 18 | ||||||||||

| EN0510 | 10 |

| EN16-20 | 20 | ||||||||||

| EN0512 | 12 |

| EN16-22 | 22 | ||||||||||

| 0.75 | EN7506 | 6 | 1.9 | 1.5 | 1.2 | #20 |

| EN16-25 | 25 | |||||

| EN7508 | 8 |

| 25 | EN25-12 | 12 | 9.1 | 7.9 | 7.5 | #4 | |||||

| EN7510 | 10 |

| EN25-16 | 16 | ||||||||||

| EN7512 | 12 |

| EN25-18 | 18 | ||||||||||

| 1.0 | EN1006 | 6 | 2.2 | 1.7 | 1.4 | #18 |

| EN25-22 | 22 | |||||

| EN1008 | 8 |

| EN25-25 | 25 | ||||||||||

| EN1010 | 10 |

| 35 | EN35-16 | 16 | 10.2 | 8.7 | 8.3 | #2 | |||||

| EN1012 | 12 |

| EN35-20 | 20 | ||||||||||

| EN1018 | 18 |

| EN35-25 | 25 | ||||||||||

| 1.5 | EN1508 | 8 | 2.5 | 2.0 | 1.7 | #16 |

| 50 | EN50-12 | 12 | 12.7 | 10.9 | 10.3 | #1 |

| EN1510 | 10 |

| EN50-18 | 18 | ||||||||||

| EN1512 | 12 |

| EN50-22 | 22 | ||||||||||

| EN1518 | 18 |

| EN50-25 | 25 | ||||||||||

| 2.5 | EN2506 | 6 | 3.3 | 2.6 | 2.3 | #14 |

| 70 | EN70-22 | 22 | 15.8 | 14.3 | 13.5 | 2/0 |

| EN2508 | 8 |

| EN70-25 | 25 | ||||||||||

| EN2510 | 10 |

| EN70-32 | 32 | ||||||||||

| EN2512 | 12 |

| 95 | EN95-25 | 25 | 17.3 | 15.6 | 14.8 | 3/0 | |||||

| EN2518 | 18 |

| EN95-30 | 30 | ||||||||||

| 4 | EN4009 | 9 | 3.9 | 3.2 | 2.8 | #12 |

| EN95-34 | 34 | |||||

| EN4012 | 12 |

| 120 | EN120-30 | 30 | 20.2 | 17.7 | 16.7 | 4/0 | |||||

| EN4018 | 18 |

| EN120-34 | 34 | ||||||||||

| 6 | EN6010 | 10 | 4.7 | 3.9 | 3.5 | #10 |

| EN120-38 | 38 | |||||

| EN6012 | 12 |

| 150 | EN150-32 | 32 | 23 | 20.6 | 19.6 | 250/300 | |||||

| EN6018 | 18 |

| EN150-40 | 40 | ||||||||||

| 10 | EN10-12 | 12 | 5.8 | 4.9 | 4.5 | #8 |

| 185 | EN185-32 | 32 | 23.9 | 21.4 | 20.2 | 300/350 |

| EN10-16 | 16 |

| EN185-40 | 40 | ||||||||||